Slaughterhouses

In Norway we have approximately 45 salmon slaughterhouses situated along the coast.

A significant amount of water is used in the slaughter process. Additionally, a substantial amount of water is used to maintain strict hygienic requirements at these plants. Based on estimates of average water consumption per kilogram of slaughtered salmon, annual wastewater discharges from this industry segment range from 8 to 10 million cubic meters.

This wastewater contains organic materials such as blood and fat residuals in the discharge. Based on discharge estimates and average organic contamination, it is anticipated that between 18,000 and 22,000 tons of organic waste is discharged annually together with this wastewater (calculated as 100 % dry solids).

The salmon slaughterhouses in Norway will be subject to new, strict discharge regulations imposed by the Norwegian government to align with EU regulations for wastewater discharges. The restricted discharge regulations will come into force on December 4th ,2023, with a one-year deadline for implementation.

To comply with the new regulations, the implementation of chemical treatment and subsequent handling of the large amounts of sludge, which has until now been discharged into the sea with the wastewater, is required. The industry has stated major challenges in meeting these new requirements, and in handling the substantial increase in waste material. Up until now, the industry has not identified a sustainable solution for chemical treatment, disposal, or reuse of the waste sludge.

MVW has developed and verified a “best in class” process for simple and cost-efficient removal of organic contaminants from the wastewater stream in existing plants. This is achieved by simply dosing and mixing our NORWAFLOC® chemicals.

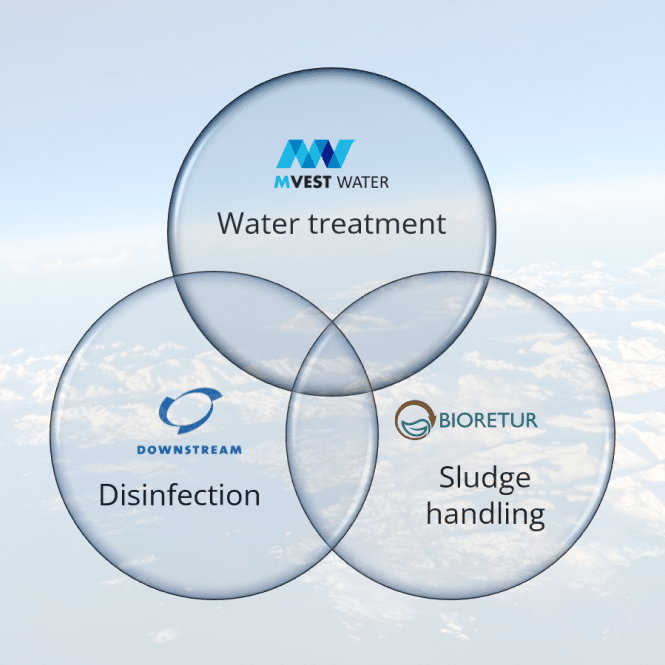

M Vest Water, in partnership with Bioretur AS and Downstream Marine AS, offers a streamlined complete treatment solution that complies with the announced restricted discharge regulations for salmon slaughter wastewater, which offer may include efficient and sustainable disposal of waste products for the clients.

The process captures pollutants and is bringing blood and fat together into large conglomerates that can be easily separated from water using existing separation equipment at the plants. After this separation, the water undergoes to obligatory disinfection before being discharged into the sea in compliance with new regulations.

This solution is launched under the umbrella of our exclusive Cooperation Agreement with Downstream Marine (DSM).

The next challenge for the industry is the sludge produced from the flotation process, which consists of 10 % solids and 90 % water. MVW has proven, and easy-to-operate equipment solutions that reduce the water content down to 25 %. However, the sludge still represents a major practical and economical challenge for the slaughterhouses as the industry segment must transport 70 -90,000 tons for disposal across Norway annually, incurring high costs.

MVW, in Alliance with Bioretur AS, now offers a total solution for treatment of bloodwater and sludge management for the salmon slaughterhouse industry. The separated sludge is dried and sterilized to a dry matter content of 90 %, with only 10% moisture. As a result, total transportation volumes are reduced to 20 -25,000 tons annually with a cost reducing reuse value.

Furthermore, the Alliance can offer to the industry an integrated WASTEWATER TREATMENT and SLUDGE MANAGEMENT SOLUTION, in which Bioretur AS, finances the equipment, remotely operates the sludge drying and manages handling and disposal.

M Vest Water, in partnership with Bioretur AS and Downstream Marine AS, offers a streamlined complete treatment solution that complies with the announced restricted discharge regulations for salmon slaughter wastewater, which offer may include efficient and sustainable disposal of waste products for the clients.

Get in touch

Explore how you can achieve cleaner and more cost-effective wastewater treatment without the use of synthetics.