Breakthrough for M Vest Water’s NorwaPol technology in Oil & Gas Industry

M Vest Water today announces a strategically important breakthrough for the patented NorwaPol® technology.

This is a patented process technology where our proprietary NorwaFloc® bio-flocculant is dosed into wastewater for subsequent removal of pollution in MVW's NorwaPol® filter.

MVW, in collaboration with one of the major US-based global oil and gas operators, has succeeded in an average treatment efficiency of 99.99% in removal of oil from produced water in a pilot at a US onshore oilfield.

The operational performance and technical results have been proven superior relative to nutshell filtration which today is the dominating technology in this global multibillion-dollar Oil & Gas treatment market segment. NorwaPol® is thoroughly tested and will be implemented at full-scale in a large Norwegian Oil & Gas process plant in Q4 2022. Our NorwaPol® technology is now technically and commercially proven.

Disruptive Technology

Nutshell filters were designed to separate crude oil from oilfield produced water in the 1970s, which remains the principal use. MVW's NorwaPol® operational performance and technical results have been superior relative to nutshell filtration.

Key benefits

- Superior technical results relative to Nutshell filters.

- Higher flow capacity than nutshell media resulting in less footprint at equal treatment capacity.

- Regenerating of contaminated filter media completed within 10 minutes versus 50 minutes in incumbent technology. Subsequently higher operational uptime.

- Media-scrubbing cycle not required in MVW's NorwaPol® filter and our efficient 10-minute backwashing sequence provides full regeneration of filter media.

- The Norwapol® filter media is expected to last for the life of the filtration system. No consume of media in the lifetime except for minor refill compensating for tiny losses during backwashing (neglectable impact on OPEX). On the contrary to nutshell filters NorwaPol® media impose no disposal costs of spent media.

- The Norwapol® filter media is made of activated and recycled substances. The media can again-and-again be recirculated and is subsequently a strong contributor to circular economy.

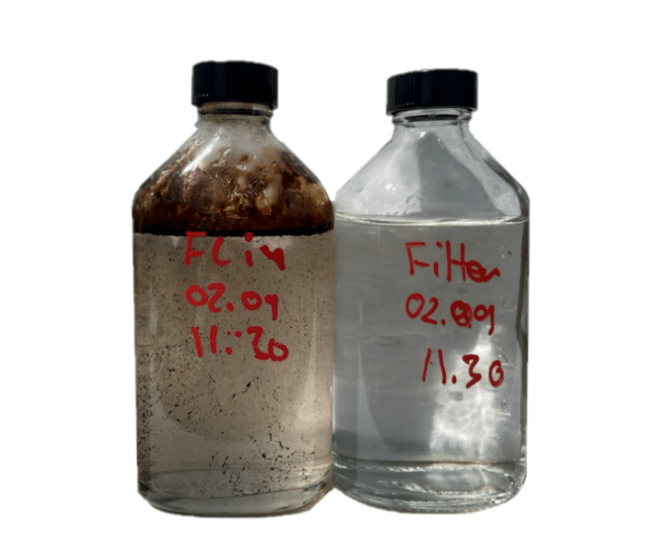

Pictured: Untreated versus treated produced water with NorwaPol® technology.

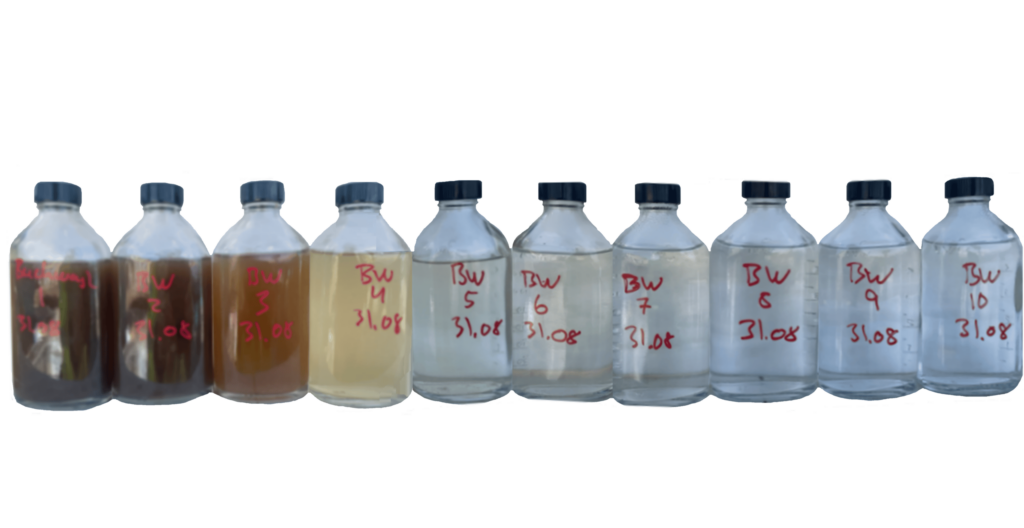

Pictured: Sample bottles where the backwash water gradually becomes cleaner minute-by-minute over a 10-minute period. The sample bottle to the right is totally clean, and also the filter media is totally cleaned after only 10 minutes. That is 5 times faster regeneration than nutshell filters in addition to significantly cleaner filter and higher treatment efficiency compared to nutshell post the cleaning process.

Produced water

Produced water is water from underground formations that is brought to the surface during oil or gas production. Because the water has been in contact with hydrocarbon-bearing formations, it contains some of the chemical characteristics of the formations and the hydrocarbons. It may include water from the reservoir, water previously injected into the formation, and any chemicals added during the production processes.

Produced water volumes have dramatically increased over the last decade and are expected to keep rising for the foreseeable future. Industry now has a need to recycle this water for use in stimulation of production and to treat the produced water to water quality applicable for agricultural use. In consequence there is an increased requirement for polishing filters capable of high performance at high flow rates.

Milestone

An important milestone has now been achieved and the company is entering the commercial phase in this Oil & Gas business segment with a disruptive replacement for the globally leading nutshell filtration process.

NorwaFloc® bio-flocculant in combination with NorwaPol® filter will be the disruptive technology to shape the future.